The Buzz on Premier Aluminum Llc

The Buzz on Premier Aluminum Llc

Blog Article

The Definitive Guide for Premier Aluminum Llc

Table of ContentsPremier Aluminum Llc Can Be Fun For AnyoneSome Known Details About Premier Aluminum Llc The 7-Minute Rule for Premier Aluminum LlcA Biased View of Premier Aluminum LlcGetting My Premier Aluminum Llc To Work

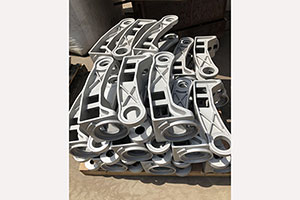

When selecting an aluminum factory for your manufacturing requirements, it's important to study numerous elements. Among one of the most essential elements to take into consideration is the experience and proficiency of the shop. Selecting a shop who has the right understanding of the aluminum spreading procedure, and the portfolio to show for it, aids to have an effective end result for your task.Having the experience and market understanding to craft your spreadings for ideal manufacturing and high quality outcomes will streamline the project. Making light weight aluminum castings calls for a complex set of processes to attain the best results. When picking a new light weight aluminum shop to partner with, ensure they have considerable industry experience and are experienced about all elements of the light weight aluminum spreading procedure: design, manufacturing, material evaluation, and product screening.

The shop ought to additionally have a tried and tested performance history of delivering extraordinary items that fulfill or surpass customer assumptions. Quality assurance ought to likewise go to the top of your checklist when selecting a light weight aluminum factory. By collaborating with a certified foundry who complies with the criteria for quality control, you can secure the honesty of your item and guarantee it meets your specs.

Some Known Incorrect Statements About Premier Aluminum Llc

This particular procedure can be automated and duplicated. Numerous parts that really complicated shapes can be made using this procedure. As a result, huge quantities of parts can be generated in simply a short time period. Before you start searching for a reliable light weight aluminum pass away caster, there are some essential things that you require to do.

You need to ask on your own what sort of aluminum pass away spreadings you need. After determining what you need, you have to state the specifications of the aluminum die castings you need. Determine the weight, thickness, dimension, and various other specifications of the aluminum die-cast you call for. It would also be much far better if you might attract and show all the measurements of the aluminum die-cast.

After having this information, you can start investigating light weight aluminum die-casting manufacturers. You can do this by merely typing the keyword" Light weight aluminum die casting producers" on the Google search engine.

A few of the concerns you need to ask yourself are whether they have actually experienced and trained operators, how long their service has functioned, or if they have some accomplishments. You can typically get the solution to these questions from the producer's website. You can investigate various other websites or outside resources to verify if the info given on the manufacturer's site is authentic.

The Only Guide to Premier Aluminum Llc

An additional point you need to think about is the supplier's capability to create light weight aluminum die-casting items. In various other words, the volume of items the maker can generate at a provided time. Some of the essential questions you need to ask on your own are whether the manufacturer can create a greater volume or can the supplier fulfill your needs.

(https://www.sooperarticles.com/authors/796316/gary-martins.html)Suppose your firm needs 10,000 pieces of specific device components from the maker within one month? You ordered this quantity; nonetheless, the supplier can only produce 5000 pieces of these device parts within one month (Foundries in Wisconsin). Because of this, you will not be able to get the amount that you purchase on time

Little Known Questions About Premier Aluminum Llc.

It is vital that you ought to make inquiries if the maker is executing an internal tooling procedure. Furthermore, you need to ask the producer just how much the cost of in-house tooling is. Bear in mind that the internal tooling procedure, which allows you to produce unique designs and forms can be an extra price.

This element straight correlates with the supplier's production ability. Foundry near me. You have to look for a supplier that can guarantee quicker distribution of items.

This suggests that there are numerous alternatives that you can choose from. That is why it is substantially advised that you should pick a manufacturer that can create various types of aluminum die-cast items.

Top Guidelines Of Premier Aluminum Llc

A lot of commonly, these aluminum die-casting items will need some decorations, machining, or completing touches. Having this in mind, you ought to try to find a supplier that can execute a variety of second finishing jobs click to read once die spreading is done. Some examples of finishing operations include Chromating, CNC Machining, Sandblasting, Powder finish, Anodized, E-coating, Damp paint, Plating, and a lot more.

Pass away spreading is one of the most cost-effective, exact, and protean manufacturing processes in the world minute. The process includes fitting molten essence, under stress, into an applicable die (planet), and formerly strengthened it can be ejected and finished (if necessary) in a selection of methods. Report this page